Assuring quality

at every stage

We are compliant with API standards (American Petroleum Institute) to enhance the safety of industry operations, assure quality, help keep costs down, reduce waste, and minimize confusion.

We have a strict

quality policy and

we sternly follow it.

We focus on continual improvement of process, quality and services to customer through upgrading the technology and skill. We are committed to achieve market leadership in welded pipes & tubes with anti corrosive coating as required and satisfy our customer through providing timely delivery and quality that meet or exceed their requirement.

Our commitment

to quality

We take pride in delivering uncompromised quality and performance by uniting best-in-class German technology and our highly skilled engineers. These four objectives define and direct Mega Pipes to better serve our clients.

Customer centricity

Improve customer satisfaction level by better understanding customer needs

Maximize production

Maximize the production yield through continual improvement and optimum use of resources

Timely delivery

Monitor and ensure timely delivery of finished product

Employee training

Continuous training and development of employees at all levels

Every HSAW pipe we make, passes through

stringent inspection & test stages

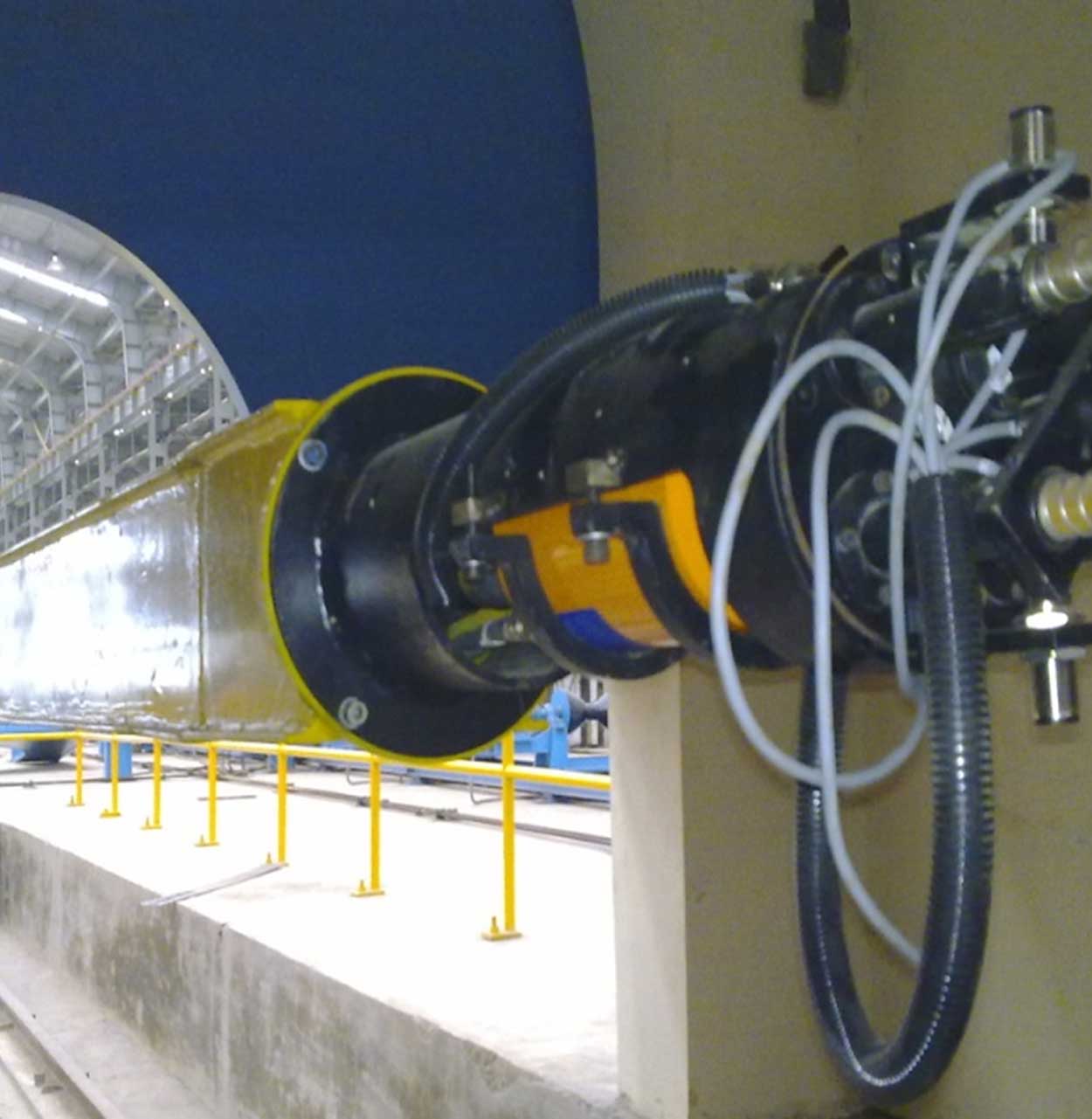

Automatic ultrasonic test machine

| Make | GE INSPECTION TECHNOLOGY |

|---|---|

| Capacity | Thickness: 6 - 25.4 mm, Test Speed (Helical) : 20 Mtrs/Min (Max) |

| Use | Ultrasonic Testing of Weld & HAZ for any imperfection |

| Features |

|

X-ray

machine

| Make | GE INSPECTION TECHNOLOGY |

|---|---|

| Capacity | Thickness: 6 - 25.4 mm, Test Speed (Helical) : 20 Mtrs/Min (Max) |

| Use | Ultrasonic Testing of Weld & HAZ for any imperfection |

| Features |

|

Magnetic particle

inspection machine

| Make | GE Dyeglo, India |

|---|---|

| Capacity |

|

| Use | Performs magnetic particle inspection of pipe ends (including end face) to detect any crack or lamination at pipe ends. |

| Features |

|

Universal Testing

Machine

| Make | Testwell Instruments, Ichalkaranji, Maharashtra, India |

|---|---|

| Capacity | Force : 0 – 100 Tons |

| Use |

|

| Features |

|

Charpy impact

test machine

| Make | Testwell Instruments, Ichalkaranji, Maharashtra, India |

|---|---|

| Capacity | Energy : 400 J |

| Use | To measure the absorbed energy, shear fracture percentage, lateral expansion upon breaking a sample in a single blow. |

| Features |

|

Spectro

meter

| Make | SPECTRO Analytical Instruments GmbH, Germany |

|---|---|

| Capacity | No. of Elements: 31 Elements |

| Use | To perform simultaneous determination of 31 alloying &

residual elements in carbon and low-alloy steels in a mass fraction. |

| Features |

|

Metallurgical

Microscope

| Make | Olympus Corporation, USA |

|---|---|

| Capability and Capacity | |

| Use | To perform metallographic analysis to determine metallic structure, phases, grain size. |

| Features |

|

Vickers hardness

tester

| Make | Fuel Instruments & Engineers (FIE) Pvt. Ltd., Maharashtra, India |

|---|---|

| Capability & Capacity | Force : 1, 5, 10, 30 & 50 kgf |

| Use | To determine macro hardness of metallic materials. |

| Features |

|

Profile

projector

| Make | Mitech Co. Ltd., China |

|---|---|

| Capability & Capacity |

|

| Use | To verify profile of test specimen |

Drop weight tear

test machine

| Make | Pragya Equipment, Indore, Madhya Pradesh, India |

|---|---|

| Capacity | Energy: 30,000 J |

| Use | To perform drop weight tear test to measure the fracture appearance or fracture ductility of material. |

| Features |

|

We have a modern laboratory set up with

following test facilities for coating quality control.

CATHODIC DISBONDMENT TESTER

(Make : Coesfeld, Germany)

To test and accurately determine the characteristics of insulating coating systems applied over steel pipes.

BOND STRENGTH TESTER

(Make : Coesfeld, Germany)

To determine the bond strength of 3lpe/3lpp coatings.

DIFFERENTIAL SCANNING CALORIMETER

(Make : Mettler Toledo)

For automatic thermal analysis of fbe powder and coatings.

MOISTURE ANALYSER

(Make : Mettler Toledo)

For automatic determination of moisture content by weight loss method.

TENSILE TESTING MACHINE

(Make : International Equipments, India)

For determination of tensile strength and elongation % of pe/pp.